FLOOD POINTS | EMBODIED CARBON ANALYSIS

Embodied carbon is the sum of all the carbon required to produce any goods or services, considered as if that energy was incorporated or 'embodied' in the product itself. The concept can be useful in determining the effectiveness of energy-producing or energy-saving devices, or the "real" replacement cost of a building, and, because energy-inputs usually entail greenhouse gas emissions, in deciding whether a product contributes to or mitigates global warming. One fundamental purpose for measuring this quantity is to compare the amount of energy produced or saved by the product in question to the amount of energy consumed in producing it.

ANNUALLY, EMBODIED CARBON IS RESPONSIBLE FOR 11% OF GLOBAL GREENHOUSE GAS EMISSIONS AND 28% OF GLOBAL BUILDING SECTOR EMISSIONS.

EMBODIED CARBON WILL BE RESPONSIBLE FOR ALMOST HALF OF TOTAL NEW CONSTRUCTION EMISSIONS BETWEEN NOW AND 2050.

Over the next 35 years, this world is projected to add 2.5 TRILLION feet squared of buildings that will be constructed or renovated in cities worldwide, or an area equal to the entire current global building stock. This is the equivalent of adding an entire New York City to the planet every 35 days for the next 40 years. The embodied cost of this amount of construction will be tremendous, and therefore taking a look at the embodied carbon cost is paramount to getting under the two degrees Celsius threshold set by the PARIS Accords.

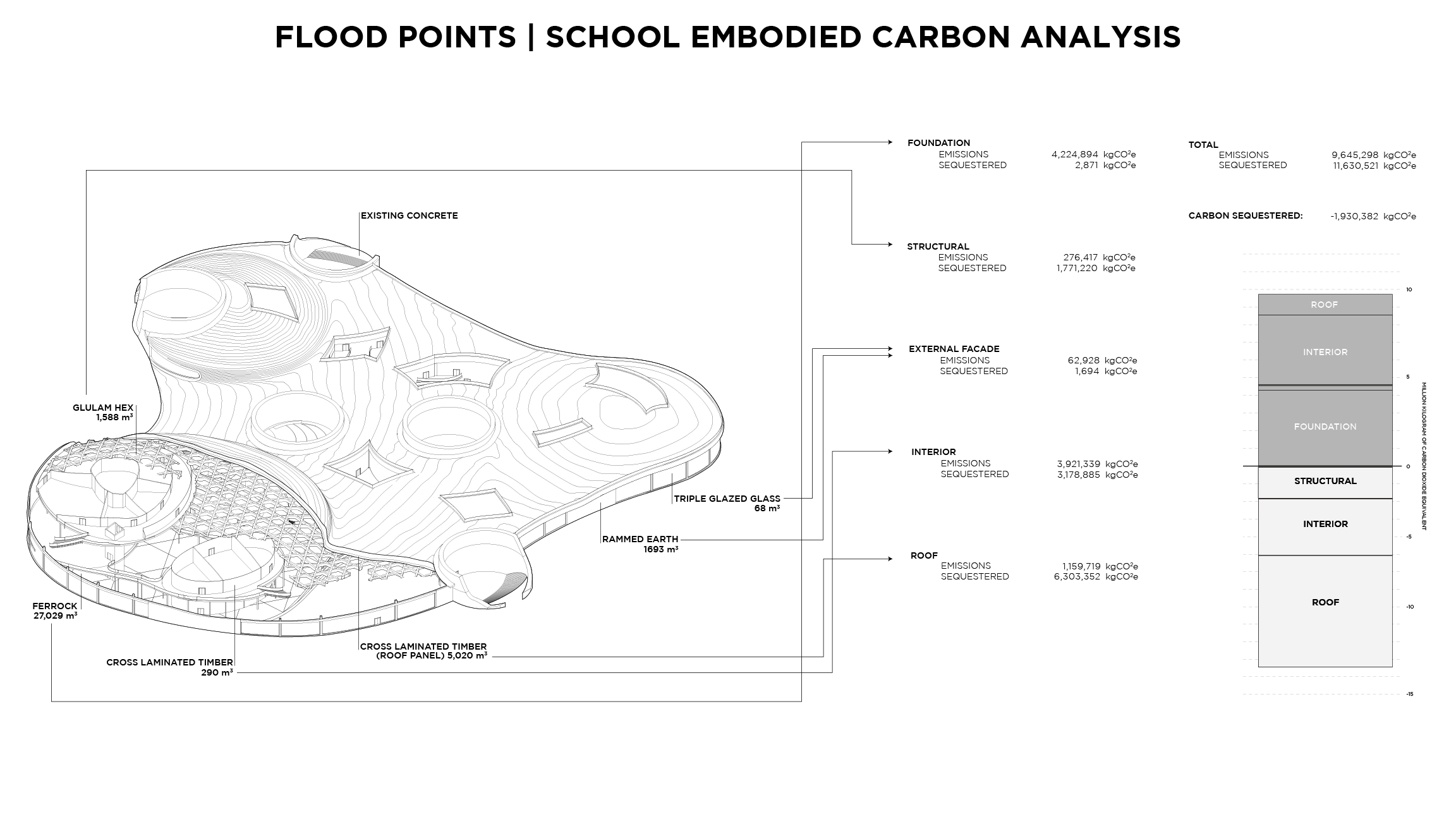

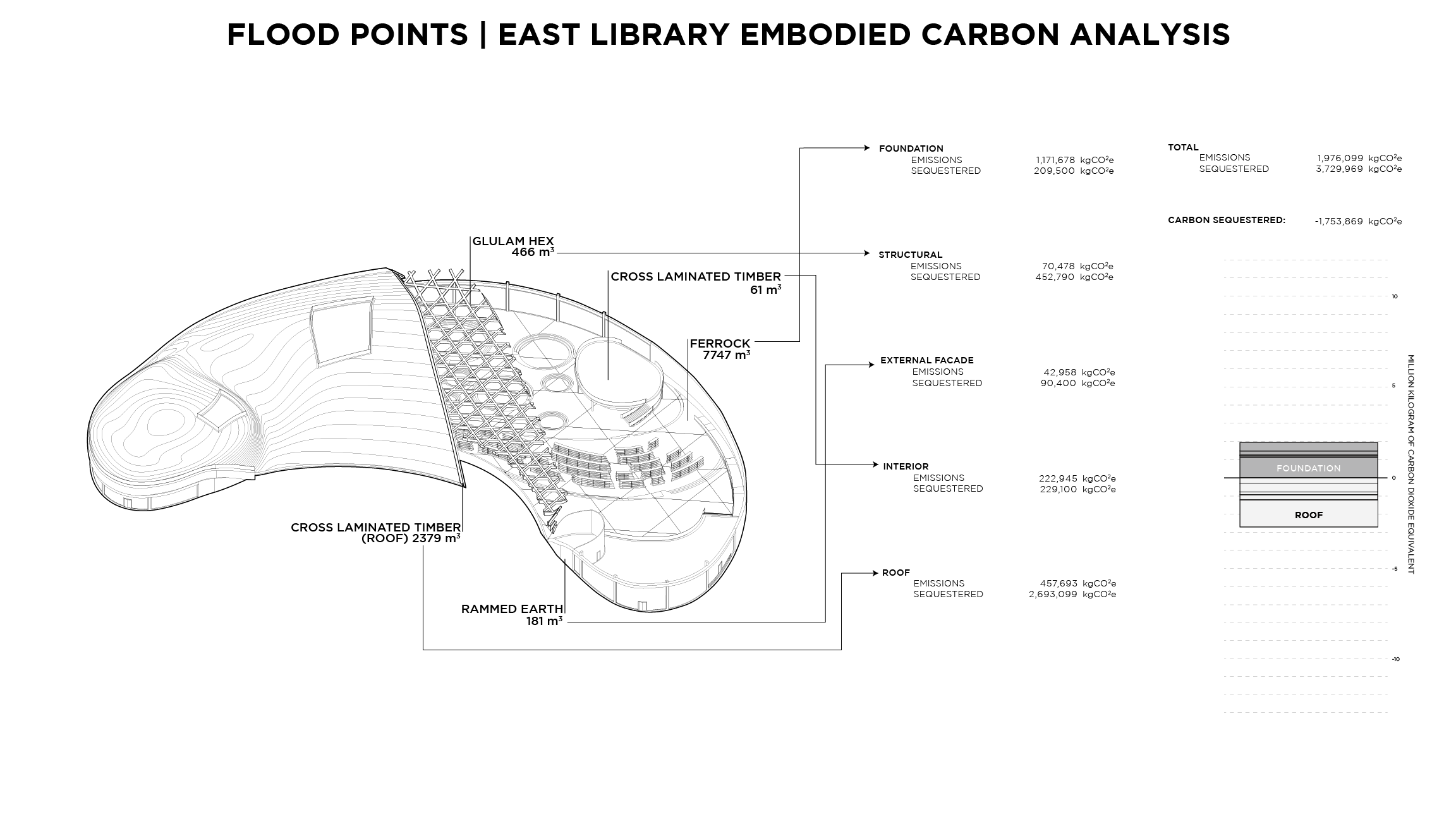

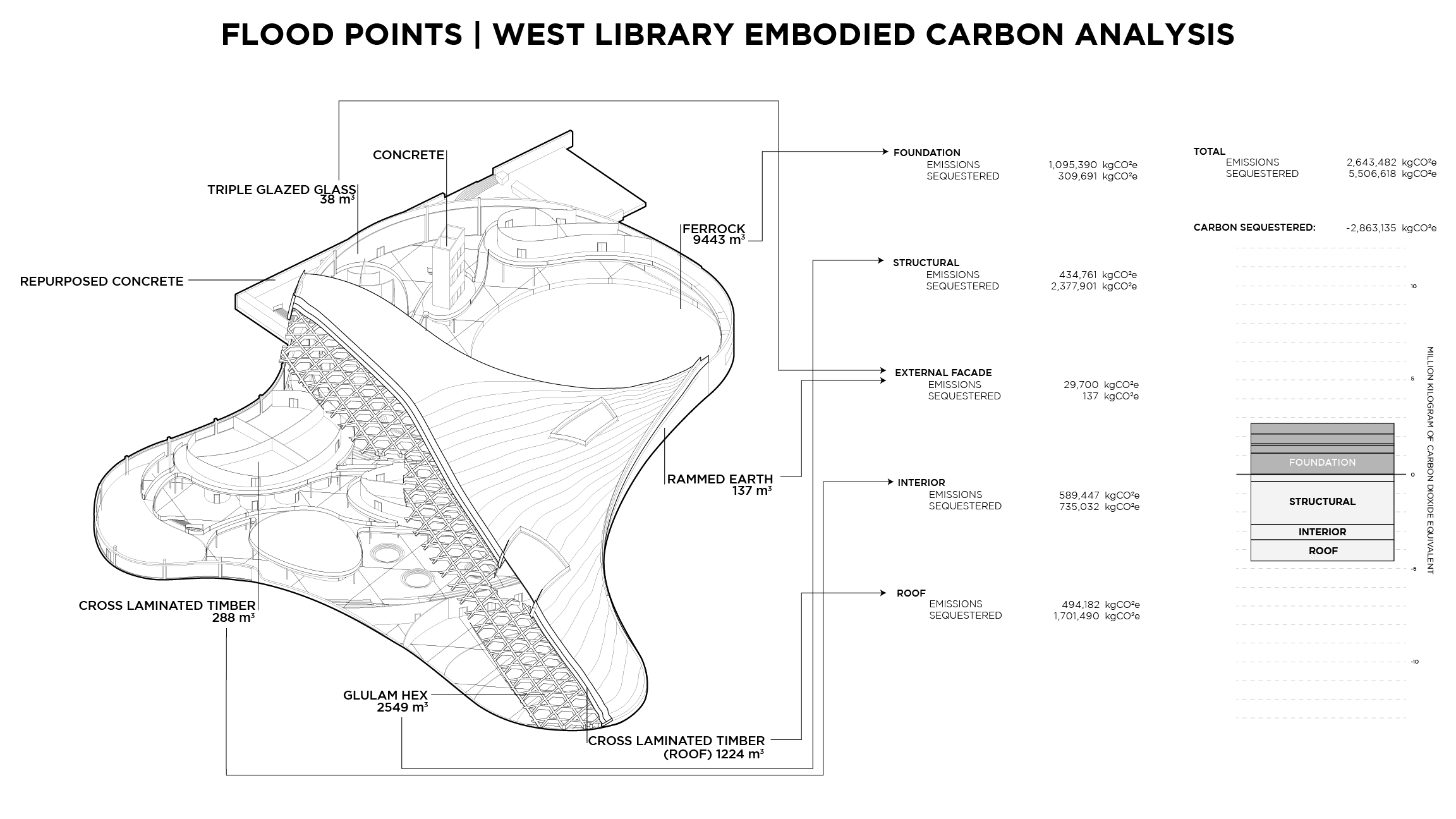

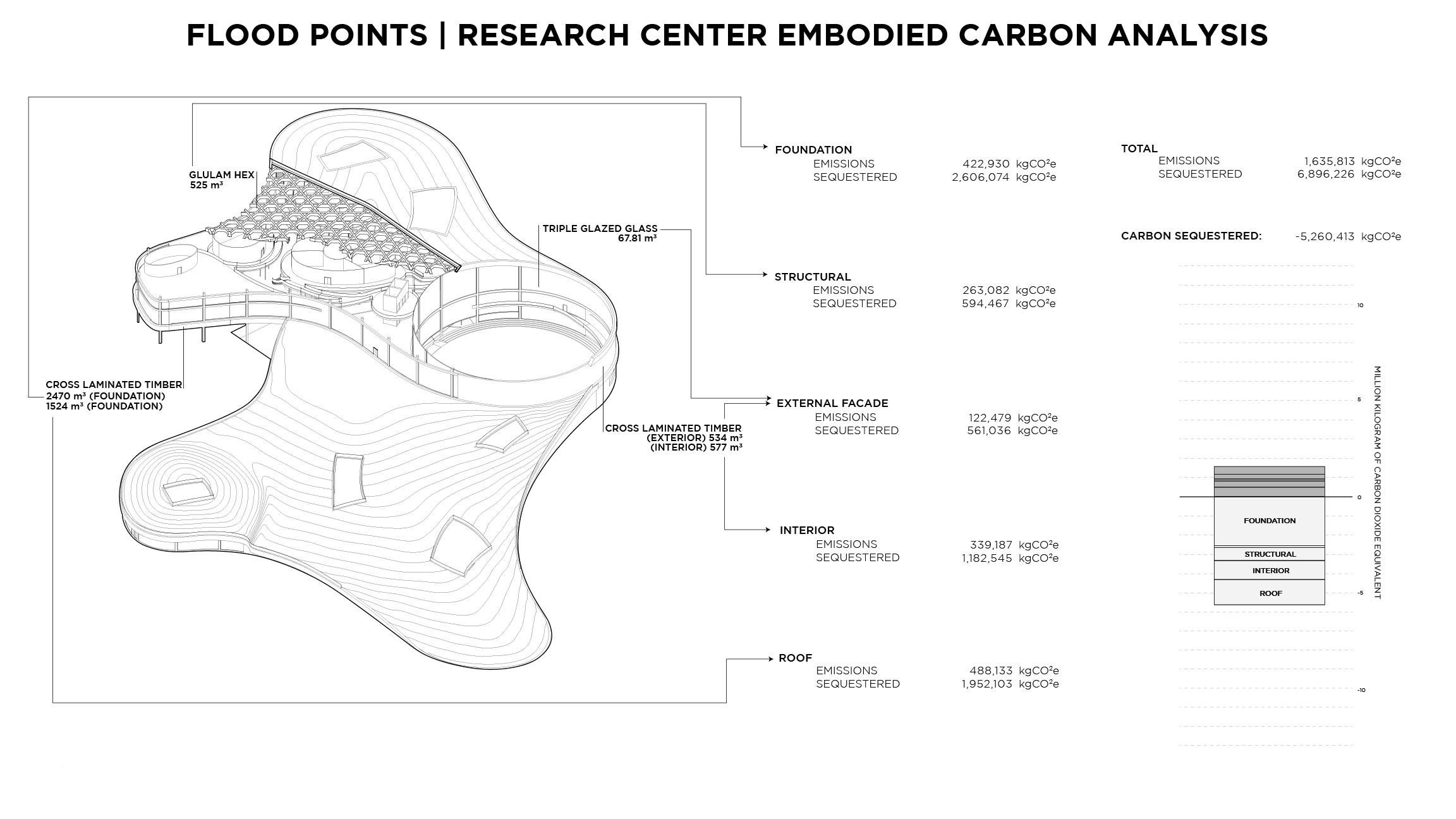

For our Capstone Project, we had embodied carbon as an issue since the start of the design phase. An embodied carbon analysis shows the amount of carbon we sequestered with the materials we judiciously selected.

MATERIAL SELECTION

TEXT ENLARGED

Keeping the problem of embodied carbon in mind, almost every material used for this project was judiciously scrutinized for their sustainability and environmental impact.

Our proposal’s buildings are of mass timber construction. Mass timber buildings are made primarily of engineered wood parts, which greatly reduce the carbon footprint of a building. Mass timber buildings are lighter than steel frame buildings due to the weight of timber versus wood, and would require less concrete and less rebar as a result. The mass timber parts include Glulam and Cross Laminated Timber, and the by-product of creating these would be used to make wood-fiber insulation that was used in the roof.

The woods that were chosen are all hardwoods sourced from New York or Quebec. The Red Cedar and White Cedar were chosen for the exterior facades because of their strength and resilience to moisture. Oak was also chosen for the project primarily for its strength and abundance. Spruce was used primarily as the column and beams system for the interior platforms of the buildings due to its flexibility.

Rammed Earth was chosen for the exterior walls of the mounds. Rammed Earth was chosen because of its low embodied carbon footprint, high thermal mass, and breathability — the walls can regulate humidity. We can also preserve the structural integrity of the walls by introducing stone water-breaks that mitigate the damage caused from heavy precipitation.

Concrete is the bane of the embodied carbon world because of its tremendous quantity for use and its requirement of rebar to maintain structural integrity. Because of this, we retrofitted much of the existing concrete on the site and looked for alternatives. Instead of using concrete, we researched and found a replacement — Ferrock. Ferrock is currently being researched in Australia as a more sustainable alternative to concrete because it does not require a high burning temperature in a kiln and can sequester carbon dioxide due to its material composition. Its sequestration allows it to become four times stronger than regular concrete. It is theoretically a carbon neutral material, and because of its composition it can serve as an anchor and reproductive point for coral and phytoplankton.

We also utilized tadelakt, a lime based waterproof plaster in the interior as an alternative to harmful waterproofing finishes that may be carcinogenic.

The glass, steel, and aluminum are essential to the structural integrity even with their high embodied carbon cost. However, we can mitigate some of these costs by sourcing them from nearby fabricators to reduce the carbon footprint of transportation. Steel and aluminum were also used in the structure and for floor to ceiling glass windows. Most of the steel is used in crucial areas where they are needed, such as framing for the windows and for joints in the roof of the buildings.

The landscape of our proposal would be made primarily from retrofitted concrete rubble that came from the site, then gravel, soil, and soil. We specifically selected different phytoremediators to remediate our site from the pollution. The materials used in construction of the buildings were also selected to become habitats for local flora and fauna after they are no longer habitable or operational due to rising sea levels.